Professional Braided Wiring Harnesses Australia | QuipTech Solutions

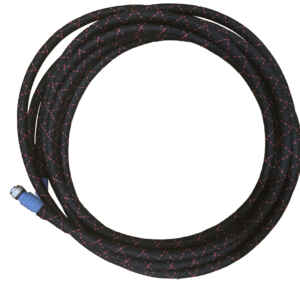

Heavy-Duty Braided Cable Solutions for Mining, Construction & Aviation Industries

Engineered for Australia’s Harshest Environments

At QuipTech Solutions, our braided wiring harnesses are precision-engineered to excel in the most demanding conditions across mining, earthmoving, construction, and aviation industries. Built to withstand continuous abrasion, extreme vibration, UV exposure, and chemical contamination, our braided cables deliver unmatched reliability when failure is not an option.

Why Choose QuipTech Braided Cables?

Our braided cables are engineered to endure the toughest Australian conditions:

✓ Continuous Abrasion Resistance

- Resists wear and tear in rugged mining and construction environments

- Maintains cable integrity under constant movement and friction

✓ Superior Vibration Protection

- Maintains secure connections in high-vibration heavy machinery

- Prevents connection failures in excavators, dozers, and mining equipment

✓ UV & Weather Resistance

- Offers superior resistance to harsh Australian sunlight and weather

- Engineered for outdoor installations across Australia

✓ Chemical & Solvent Resistance

- Stands up to exposure from hydraulic fluids, fuels, and industrial chemicals

- Maintains performance in contaminated environments

✓ Sudden Movement Protection

- Ensures consistent performance under heavy strain and shock loads

- Flexible design accommodates equipment movement without damage

Industries We Serve

Mining Operations

- Excavators – Heavy-duty mining excavator installations

- Dozers – Large dozer installations with proven reliability

- Loaders – Heavy-duty mining loader applications

- Conveyor Systems – Continuous operation cable solutions

Construction & Earthmoving

- Machine Guidance Systems – Precision positioning equipment

- Excavator Applications – Sensor and control system connections

- Dozer Installations – Blade and sensor applications

- Mobile Equipment – Fleet vehicle installations

Aviation & Aerospace

- Avionics wiring harnesses

- Ground support equipment

- Aircraft maintenance applications

Our Braided Cable Advantages

🔧 Reduced Downtime

- Durable construction means fewer failures and costly repairs

- Proven Track Record: Zero damage returns on our installations

⚡ Enhanced Performance

- Reliable connections keep operations running smoothly

- Maintains signal integrity in electromagnetic environments

💰 Cost Savings

- Longevity and durability reduce replacement costs

- Lower total cost of ownership over equipment lifecycle

Technical Specifications

Construction Features:

- Braided Shield: Tinned copper braid for EMI/RFI protection

- Core Materials: High-grade copper conductors

- Insulation: Chemical-resistant, UV-stable compounds

- Temperature Range: -40°C to +125°C operating range

- Voltage Rating: Up to 1000V applications

- Bend Radius: Optimized for tight routing requirements

Compliance Standards:

- Australian electrical safety standards

- Mining industry specifications

- Aviation wiring standards (where applicable)

- IP67/IP68 environmental protection ratings

Custom Design & Manufacturing

Professional Workshop Manufacturing

Each harness is custom-designed to your specifications and built to order in our professional workshop, ensuring:

- Perfect fit for your specific equipment and application

- Integration with existing control systems

- Compliance with Australian mining and construction standards

- Quality control throughout the manufacturing process

Design Services Include:

- Cable routing analysis – Optimal path planning for your equipment

- Connector selection – M12, TNC, N-Type, and custom connectors

- Length optimization – Exact measurements for your installation

- Environmental assessment – Protection level matching your conditions

Proven Applications & Expertise

Heavy Industrial Equipment

- Mining Excavators – Heavy-duty system installations

- Construction Dozers – Precision control applications

- Mobile Equipment – Fleet vehicle installations

- Specialized Machinery – Custom sensor and control connections

Quality Assurance

- Zero Failure Rate – Proven track record of reliable installations

- Professional Installation – Expert technicians and quality workmanship

- Comprehensive Testing – Each harness tested before delivery

Professional Services

Installation & Support

- On-site Installation – Professional technicians across Australia

- System Integration – Complete control system setup

- Technical Support – Ongoing maintenance and troubleshooting

- Custom Solutions – Tailored to your specific requirements

Quality Standards:

- Professional Workmanship – Pride in every installation

- Reliable Service – We do what we say, when we say we’ll do it

- Technical Excellence – Staying ahead with latest technology

- Customer Focus – Building lasting partnerships

Get Your Custom Braided Wiring Quote

Contact QuipTech Solutions today for professional braided wiring harness solutions tailored to your specific requirements.

📞 Contact Information:

- Website: www.quiptechsolutions.com

- Service Area: Australia-wide professional installation

- Specialization: Custom braided wiring harnesses for industrial applications

🏭 Professional Manufacturing:

Custom design and manufacturing services available. Expert installation and support across Australia.